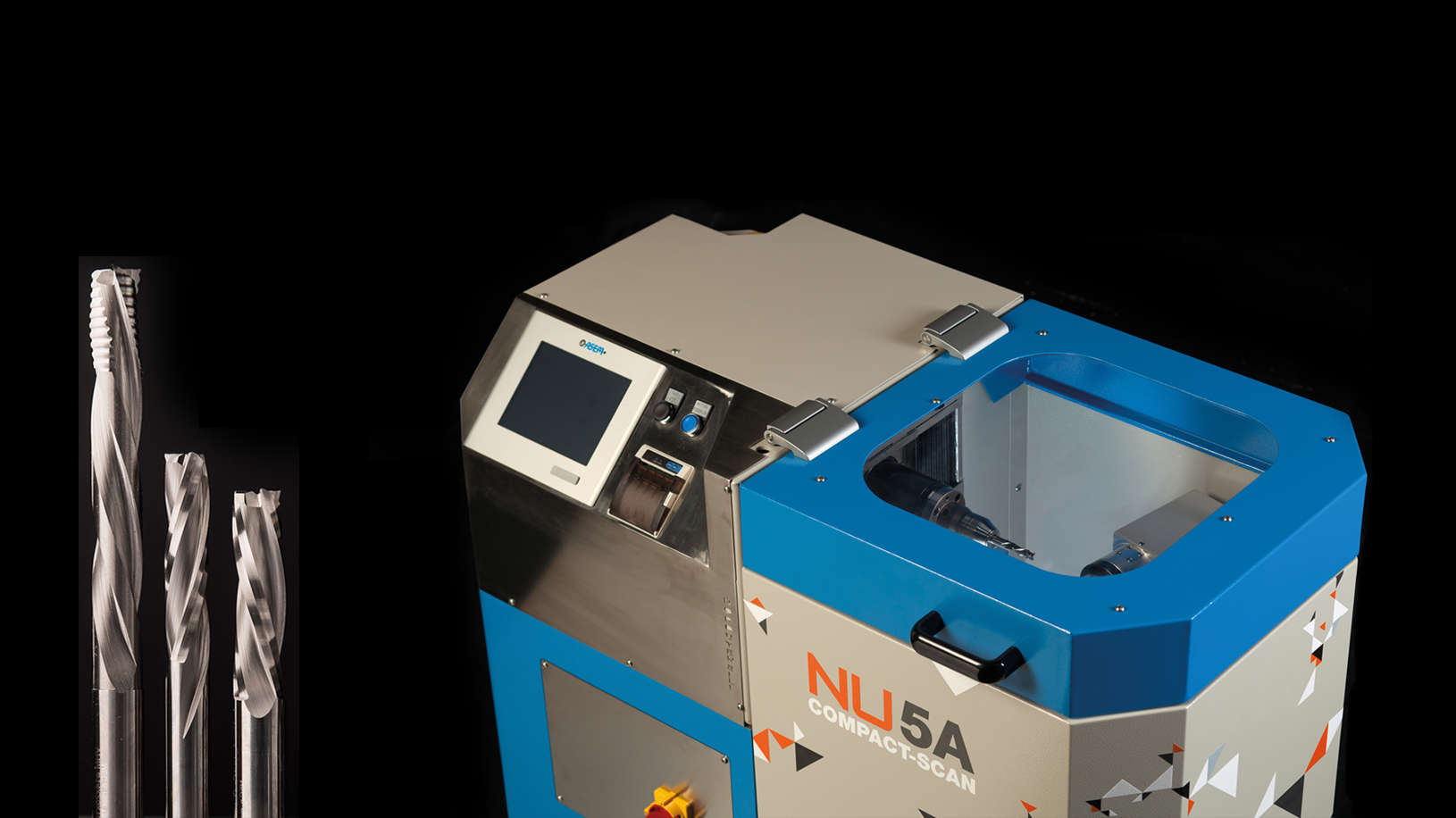

The NU5A COMPACT SCAN does not require specialist operators. Very little time is needed for training on how to use the machine.

The NU5A can regrind compression router bits?

Yes, the current software version supports compression bits with 1+1, 2+2, 3+3 flutes.

Which parts of the tools can be reground?

NU5A can regrind the flute, the primary and the secondary angles of the OD body. Also it can regrind the gash, primary and secondary angles of the end. It is possible to select all of the operations or deselect any of them.

Is it possible to crash the wheels?

Is it possible to crash the wheels?

No, the collision avoidance system prevents any crash between the wheels and the chuck.

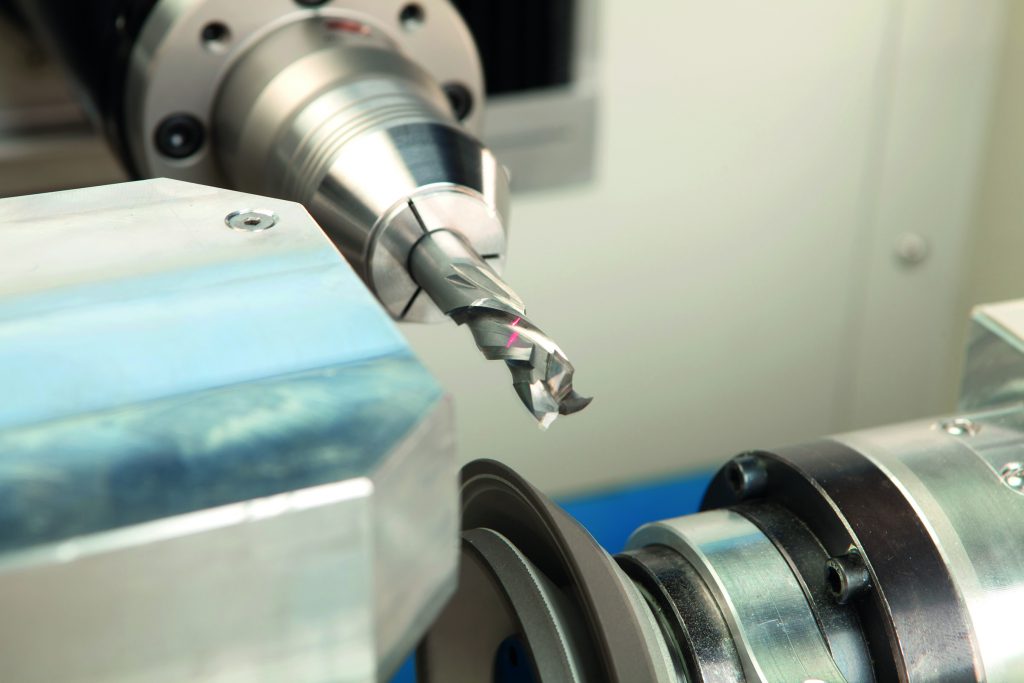

Can the NU5A analyze and grind drill bits?

The current software recognizes only spiral router bits and end mills. Drill bits will be introduced in a future software release.

How is the wheel wear managed?

The laser scanner can measure and compensate the wheels’ wear.

Can the NU5A grind chip brakers and roughers?

The software can find souch features of the tool (if the depth is more than 0.2 mm) and disable the grinding of the OD.

What are the minimum and maximum tool diameter that the machine can grind?

The NU5A comes with a complete set of collets and mini-chucks to support all the range of diameters from 3mm (1/8″) to 25mm (1″).

What are the tool’s materials supported by NU5A?

The machine can grind tool’s made of tungsten carbide and high speed steel. Brazed tools are not supported.